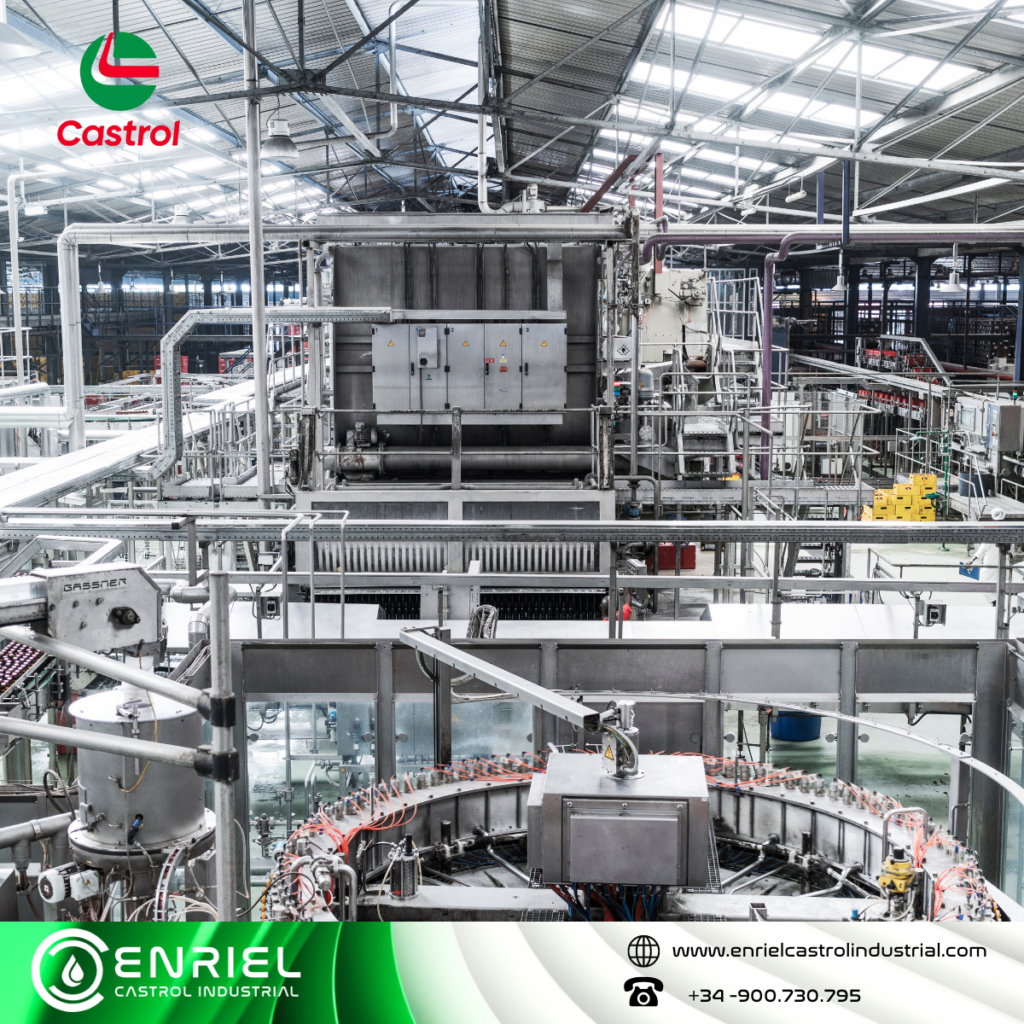

The importance of lubricants in the food industry.

Castrol engineers understand the challenges of lubrication for the food and beverage industry and are working to develop a wide range of products that combine the performance of premium lubricants with the use of food grade base oils and raw materials to lubricate everything from hydraulics to gearboxes, bearings and compressors at all temperatures.

Castrol’s food grade lubricants are NSF-H1 certified and are approved for use in kosher and halal food production as well:

- They contain no naturally occurring animal by-products or genetically modified organisms (GMOs).

- Perfect for use in facilities where vegetarian and nut-free foods are prepared.

- Approved and endorsed by a large number of original equipment manufacturers

- Help extend equipment life and improve equipment performance

- Extend maintenance intervals and increase productivity

- Reduce maintenance costs and overall consumption and waste

- Contribute to safe food production

Characteristics of food grade lubricants.

The food, beverage and pharmaceutical processing industry has become increasingly complex, integrating processes and inputs to ensure food safety, as consumer health is a priority. Therefore, lubrication in the food industry encompasses hydraulic systems, gearboxes, chains, air and refrigeration compressors, vacuum pumps, among other mechanisms that require a certified food grade lubricant.

To ensure compliance with quality, safety and security standards, industries require lubricants with low aromatic content, suitable for incidental contact between the inputs used for production and the chemicals in the oils or hydraulic fluids.

Food grade lubricants contain base oils, thickeners and performance additives in specific dosages to produce safe formulations. This is important because although cleaning processes require a high level of care, there is a risk of transferring small amounts of lubricant onto food handling surfaces.

Should cross-contamination occur, the company must determine whether the final product is suitable for distribution, which can result in losses due to recalls or lawsuits by affected consumers. Therefore, using food grade lubricants avoids costly mistakes.

Another feature of food grade lubricants is allergen control, as manufacturers carefully select formulations to avoid the most common allergenic substances that can affect the consumer.

Food lubricants are odourless, tasteless, inert and safe for human consumption in small portions, making them suitable for unavoidable contact with food, as they are used in conveyor belts, mixers or pumps during cooking, canning, cutting, packing or bottling processes.

- They are used in machines that do not have direct contact with food products, such as industrial machinery, however it is important that they comply with strict guidelines such as not containing carcinogens, teratogens, mineral acids and heavy metals such as arsenic, mercury, lead, antimony and selenium.

- They are soluble oils used to prevent corrosion between metal parts of conveyor belts or hooks; they are edible, safe and biodegradable.

Food grade lubricants have properties of resistance to high pressure and temperature, wear, loads, corrosion, contaminants, steam, acids, sugars, among other elements present during food production.

We leave you with this interesting article from Noria Corporation where they talk about the importance of lubricants suitable for food use and the different existing certifications.

The importance of food grade lubricants – Noria Latin America

La importancia de los lubricantes aptos para uso alimentario – Noria Latín América

For more information, please contact us.

Phone: +34 – 900.730.795

Mail: info@enrielcastrolindustrial.com

Machine diagnostics in 60 seconds: how it works in practice

New interchangeable drill bits from WIDIA.