Industrial drive chains: how to avoid production downtime and extend the life of your machinery.

Why are transmission chains key to your industrial line?

In industry, the right transmission chain can be the difference between a production line that runs smoothly and one that generates breakdowns and unforeseen costs.

After more than 40 years in the sector, at Enriel we have seen that choosing the right chain has a direct impact on the availability of machinery, maintenance and the profitability of each plant.

Drive chains are not simple mechanical components, but the heart of power transmission in sectors such as food, agriculture, construction and packaging. When correctly sized and selected, they help to reduce vibrations, improve energy efficiency and extend the service life of machinery.

Advantages of the chains we distribute at Enriel

Transmission chains offer an optimal balance between reliability, versatility and total cost. This combination allows industrial companies to work with greater stability, minimise unplanned downtime and simplify maintenance.

In addition to supplying components, at Enriel we provide specialised technical advice to analyse each application, working conditions and load requirements, recommending the most suitable solution for each production line.

In this way, each project is approached with a view to not only replacing a chain, but also improving the transmission system as a whole. You can see our available products on the website Catalogue

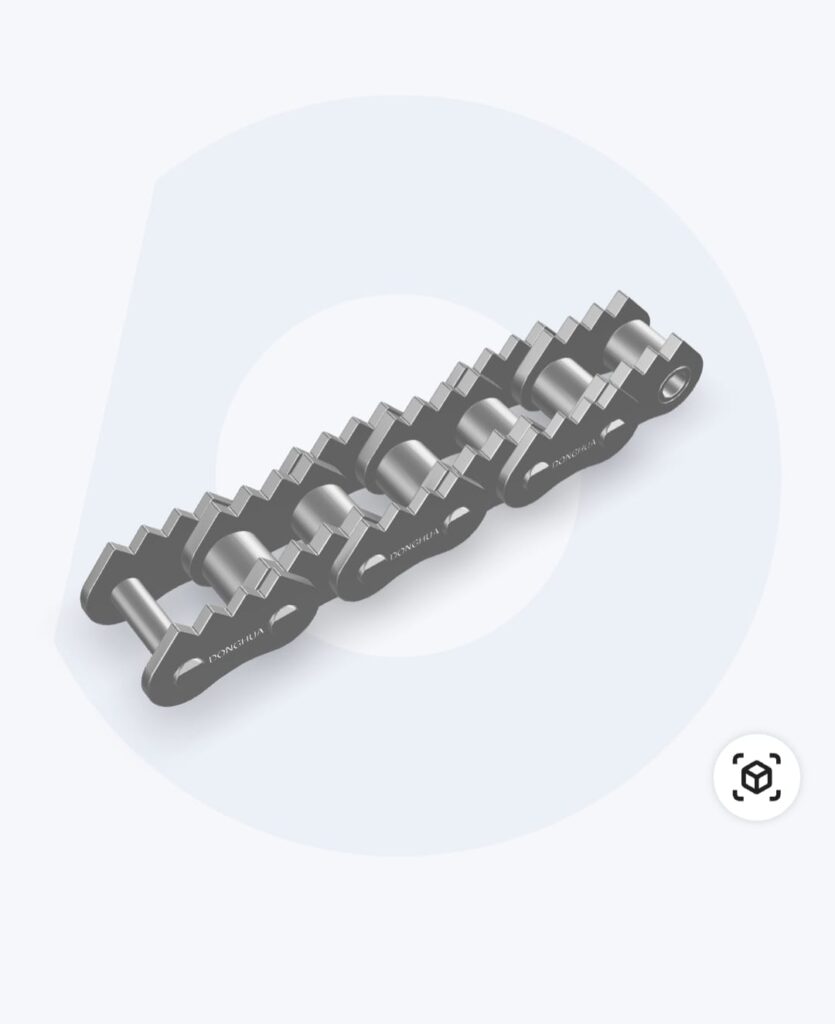

Short pitch chains for compact designs

These are standard transmission chains widely used in various industrial applications. With less distance between the chain links, they allow the use of smaller sprockets. These chains are ideal for situations requiring compact and powerful transmissions, such as machinery and production lines where space is limited and efficiency is crucial.

Double-pass chains for long centre distances

They offer an extended version of short pitch chains. They are more cost-effective as they contain fewer components per metre, the distance between rollers is twice that of a standard chain, and they require larger sprockets. These chains are ideal for applications where cost savings are important without compromising performance, such as in the packaging industry.

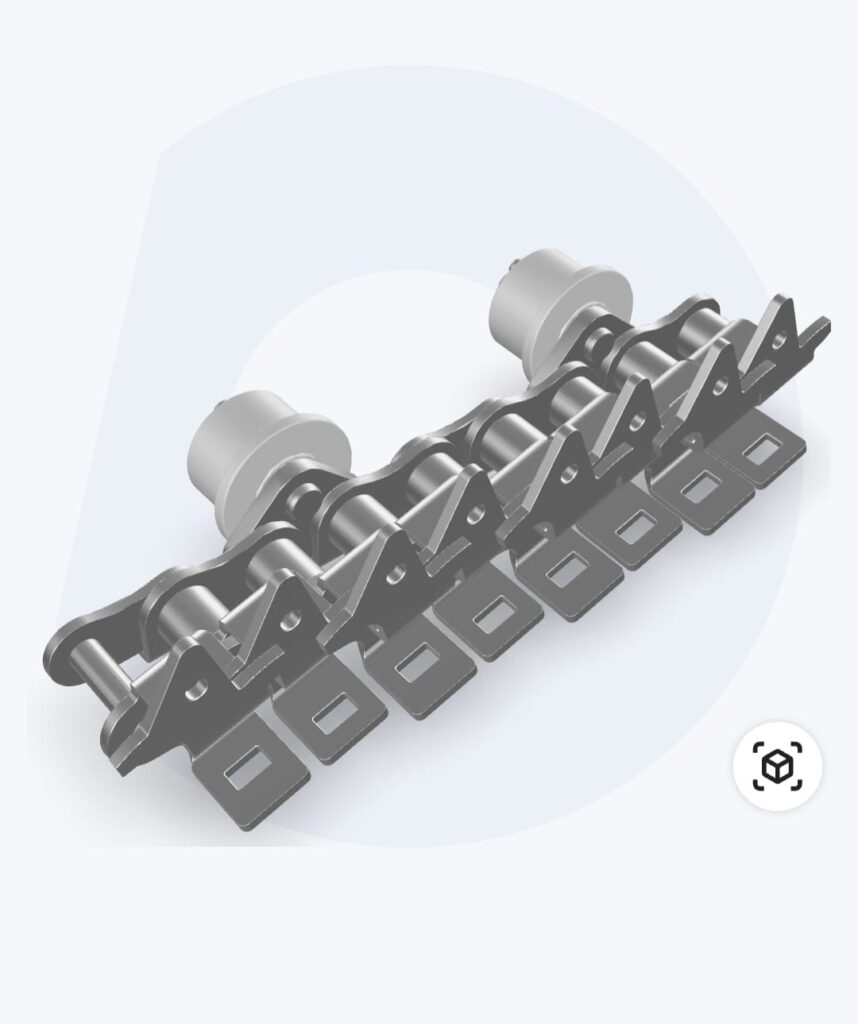

Standard working chains for demanding conditions

These are reinforced versions of standard chains, designed specifically for heavier applications. These chains are commonly used in agriculture and construction, where durability and high breaking loads are essential. With standardised specifications and dimensions, they are compatible with a wide variety of equipment and facilitate replacement and maintenance operations.

Side curve chains for complex layouts

Side bend chains are specifically designed to flex and bend sideways, making them ideal for installations with complex layouts. Typical applications include bakeries, greenhouses, and transport systems where the route is not linear and tight turning radii are required.

Rotary chains for continuous rotation and heavy loads

Rotary chains are used in applications that require continuous rotation and high load management. Their construction allows for stable and safe operation in environments where mechanical stress is constant and line stoppages result in high production costs. Ideal for construction or mining..

Bushing chains for abrasive environments

In bushing chains, standard pins are replaced by bushings, reducing the weight and cost of the system. This design is particularly suitable for abrasive working conditions, as bushings are more resistant to dirt and particles that could damage other types of chains.

Sectors where our chains make a difference

The transmission chains distributed by Enriel are integrated into food, pharmaceutical, and cosmetic production lines where cleanliness, reliability, and continuity of service are essential. They are also used in machinery where dust, water, and load changes require robust and easy-to-maintain solutions.

In packaging and the industrial sector, these chains enable variable loads, intensive work rates and continuous cycles to be handled, maintaining stable performance over time.

Having a specialised supplier such as Enriel makes it easier to adapt each type of chain to the specific needs of each sector and each plant.

Technical advice on selecting the appropriate drive chain

Choosing the right chain is not just a matter of consulting a catalogue, but of understanding each customer’s environment, loads, speeds, cycles and production objectives. Our technical team will accompany you throughout this process, evaluating alternatives and proposing solutions that reduce downtime, extend the useful life of your machinery and optimise your investment.

At Enriel, every part counts, and we work with the vision of becoming a long-term technology partner for industrial companies.

If your plant needs to review its transmission chains or you are looking to improve the reliability of your line, our team is available to offer technical advice and help you select the best solution for your needs. Contact – Enriel

Aluminium machining: a real challenge with precise solutions